Norac’s wall systems are designed to meet the following criteria: quality, flexibility, fire, sound, weight and ease of installation. Based on new requirements for improved acoustic insulation, Norac has developed a series of acoustic walls, which offer documented sound reduction properties of up to Rw=53 db.

Walls K-600

K-600 is designed with integrated joint profiles for rapid installation, leaving a flush surface with single seam joints. Available in standard or modular system.

Approved B-15 available for several wall types.

The system have been shock tested. More information available on request.

K-panels are also available in aluminium construction in B-15 with considerable weight savings.

See technical descriptions below.

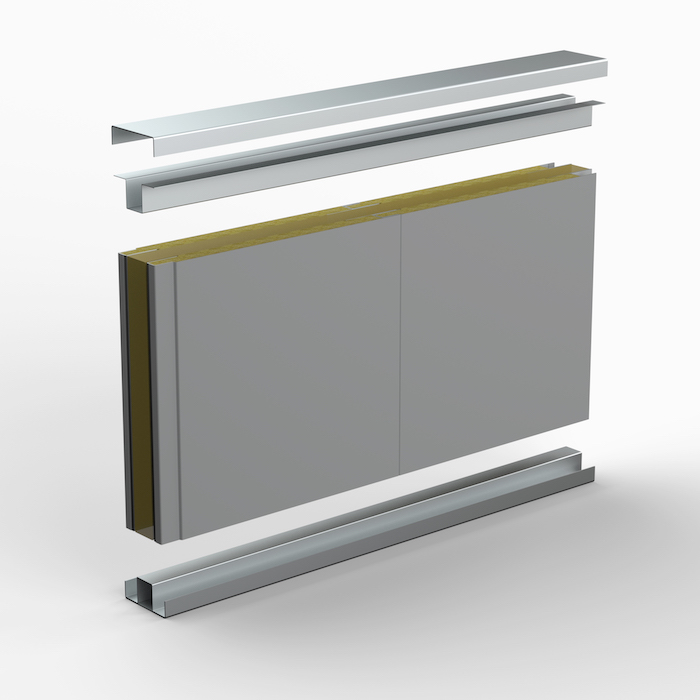

Walls Q-600 / CF-600

Q-600 is acoustic wall system of sandwich construction with an excellent sound reduction quality.

Q-600 is a rigid system with integrated joint profiles which allows for easy and rapid installation.

Flush surface with single seam joints. Available as a modular system.

50 mm panels available with vertical cable ducts in B-15.

70 mm panels have the possibility to draw cables horizontal and vertical.

43 – 49 dB

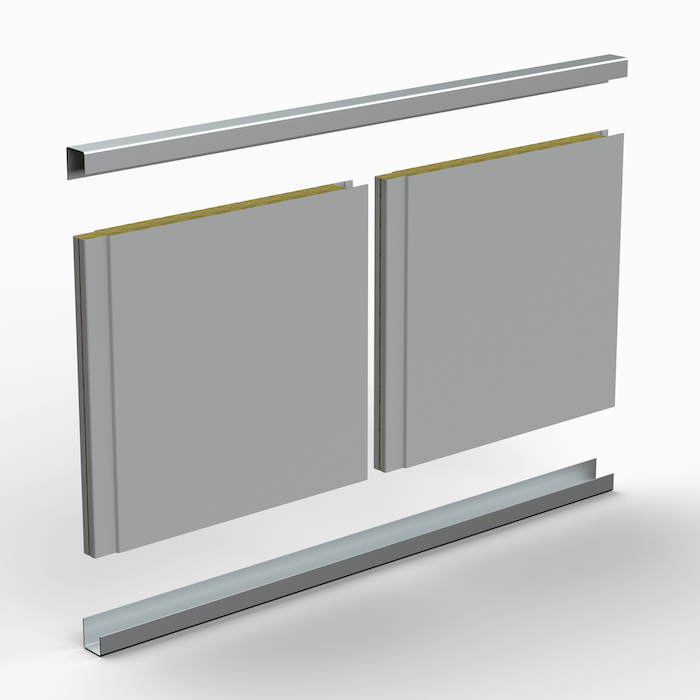

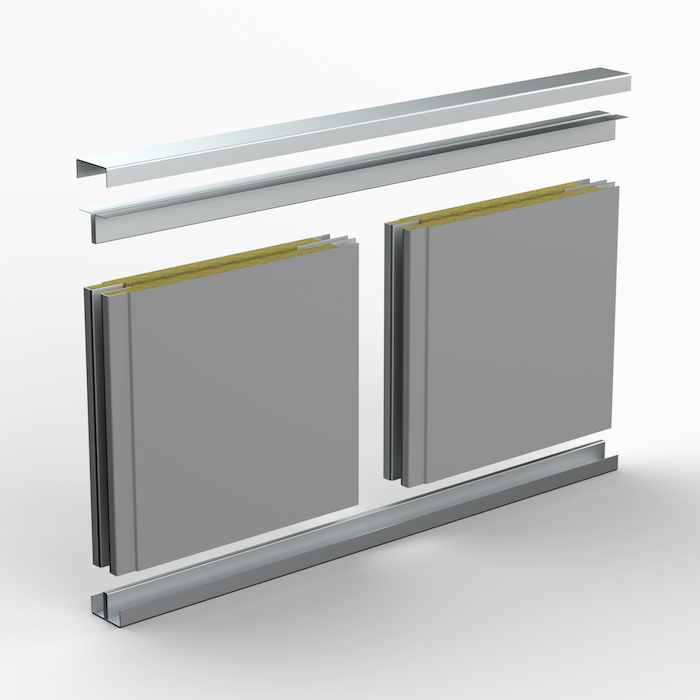

Walls C-600 / CS-600

C-600 is an acoustic double wall system with two independent wall elements installed in the same profile system.

Available as standard or modular system.

Allows installation of electrical cables before completing assembly (in 70 mm version).

45 – 49 dB

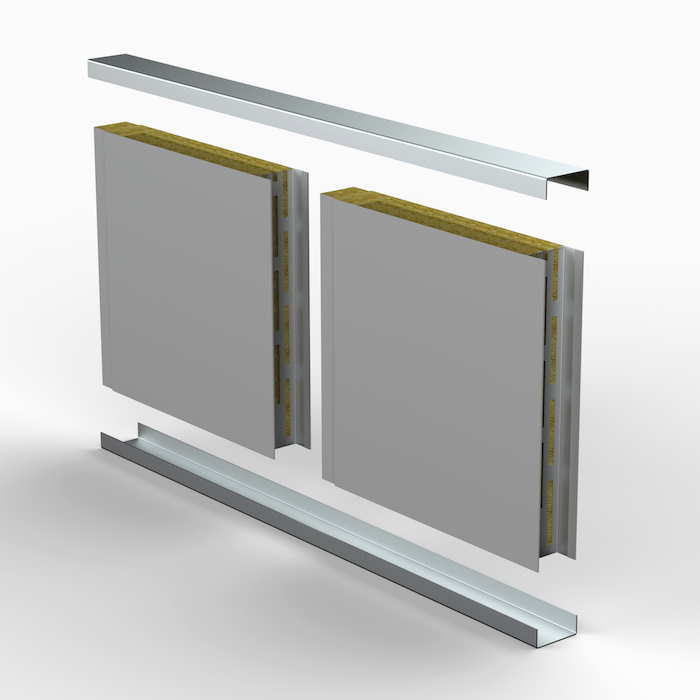

Walls CSG-600 / 70

The use of additional insulation between the two panels of a CS-600/70 wall improves the sound reduction by an amazing 4dB compared to the CS system on page 15.

Note that building thickness is not more than 70 mm.

53 dB

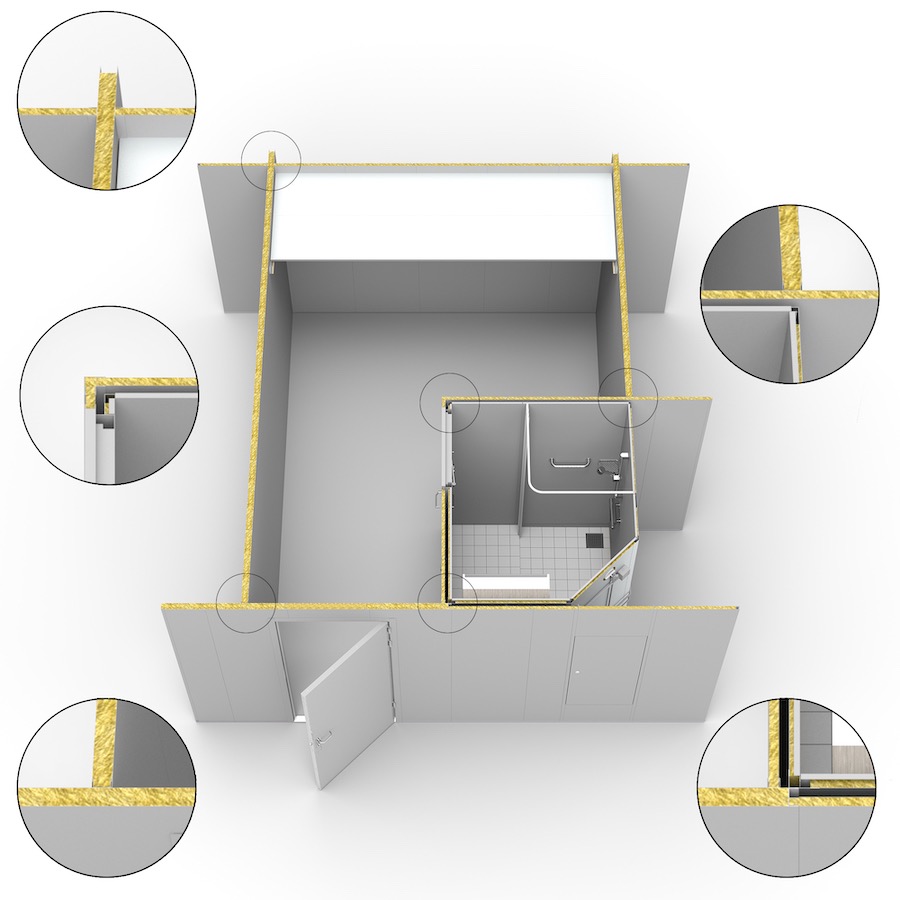

Walls Example of

standard systems

A standard system is a flexible system allowing adjustments onboard the vessel during construction. The panels are delivered In one standard size and are cut to fit according to the on site measurements with use of standard profiles.

Profiles are designed to leave as few visible screws/rivets as possible.

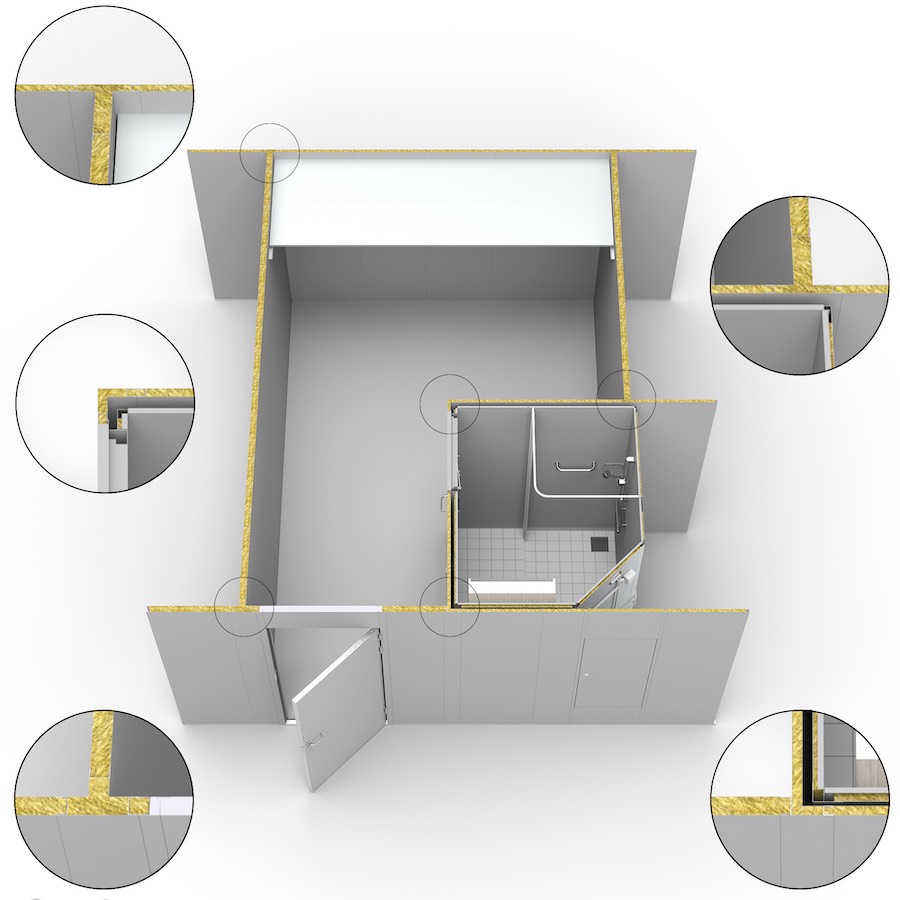

Walls Example of

modular systems

A modular system is a fully tailor-made system to avoid adjustments and cutting onboard vessels. These systems reduce the installation time for the yard and more importantly reduces costs.

A modular system leaves a smooth finish with no external profiles, no visible screws/rivets.

It is appreciated just as much for commercial vessels and offshore rigs as it is for cruise vessels.